8.4

Sustainable innovation

Essential idea: Sustainable innovation facilitates the diffusion of sustainable products and solutions into the marketplace.

Sustainable innovation yields both bottom line and top line returns as developing products, services and systems that are environmentally friendly lowers costs through reducing the resources required. Designers should view compliance with government legislation as an opportunity for sustainable innovation.

Complexity and timescale of sustainable innovation

Manufacturers and governments have difficulty in achieving close relationships due to differing understandings of the concepts of sustainability and the timescales necessary for its achievement and maintenance.

Complexity: Sustainable innovation relies on cooperation between different stakeholders such as the government and manufacturers. It is a complicated/ intricate process that takes a long time to implement.

- 3 P's - people, planet, profit

- Environmental considerations

- Stakeholders

- Environmental footprint

Timescale: The huge timescale means that sustainability is difficult to maintain as conditions/criteria can change significantly, for example, a lengthy period of economic downturn. Sustainable innovation is a hugely complex concept that requires a long time for implementation (depending on the nature of innovation).

|

| Top-down and bottom-up strategies |

Top-down strategies

Different strategies for innovation: top-down

- Strategies are implemented from the 'top' such as global or national government initiatives.

- Management of resources, finances, higher ups

- It provides targets and measures for sustainability

- When considering sustainable innovation, designers are usually more comfortable with top-down strategies as it means investment and resources are more predictable and reliable

- eg. government legislation for environmental impact margins

At its most basic, this is the breaking down og a system into component parts. From a corporate strategy perspective, a top-down strategy means that the leadership level will determine the goals and how much each department or individual employees will contribute to meet those goals.

- designers are more comfortable with top-down strategies as it means investment and resources are more predictable and reliable.

|

| Difference between top-down and bottom-up |

Bottom-up strategies

Different strategies for innovation: bottom-up

- Strategies implemented from the 'bottom' such as regional or local (city or town level)

- Designers involved with bottom-up strategies are usually enthusiasts for the project and willing to make a commitment even though it may not be cost effective to do so.

At its most basic, this is the piecing together of components or systems in order to give rise to a more complex system or product. From a corporate strategy perspectives, a bottom up strategy methodology means that the leadership level will determine the overall goals, but the workforce will assist in developing the mechanisms and ideas to meet that goal;

- regional/ town level local initiatives

- generally enthusiasts for the projects

- changing of associated policies and changing political scene may lead to issues.

Government intervention in innovation

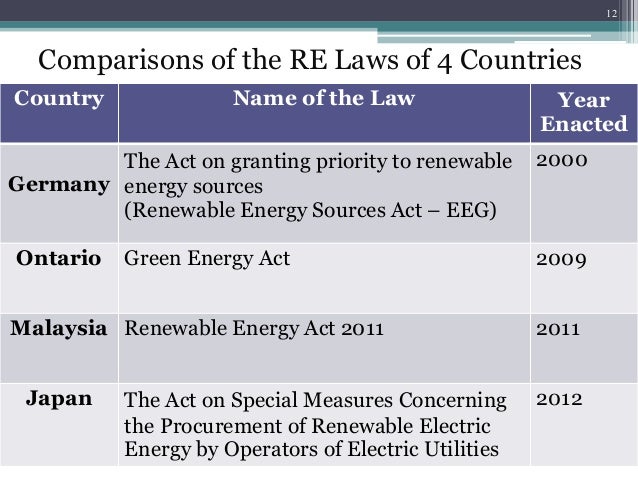

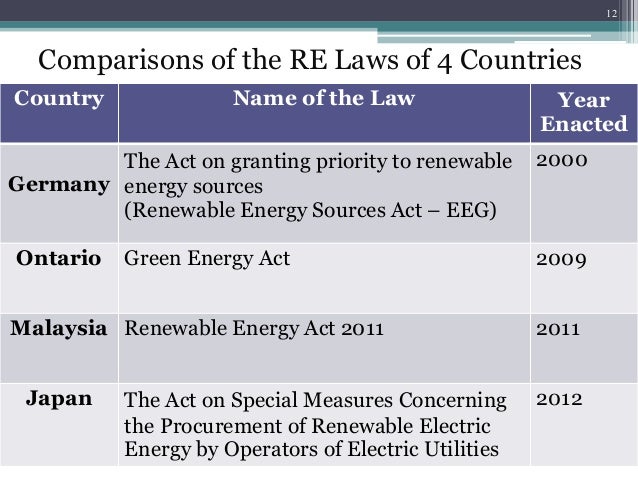

Setting and policing rules to avoid or limit environmental issues caused by undesirable technologies. For example, Renewable Energy Law relates to the issues of development and implementation of renewable resources.

|

| Renewable energy law |

|

| Philippines Renewable Energy law |

Providing consumers with information and guidance in the choice of products and services that are more sustainable.

|

Schools embrace the SDGs

|

To penalize environmentally damaging technologies and influence consumer choice of sustainable products and services.

To stimulate and support sustainable innovations. Sustainable innovation can cast the company profits so governments offer financial help or tax breaks.

|

| The US Environmental Protection Agency |

Macro energy sustainability

Macro energy sustainability focuses on how a nation utlizes energy in a sustainable manner.

- May be influenced through international treaties and energy policies, instruments for change and disincentives, and national systems changing policies when government leadership changes.

- Macro-sustainability is the area of sustainable development that focuses on how a nation, region or the entire world would establish large scale behaviours for sustainability; the Kyoto Protocol would fall into this category.

EXAMPLE: KYOTO PROTOCOL

Micro energy sustainability

Micro energy sustainability focuses on local initiatives. It can be influenced by the role of the government in raising awareness and changing attitudes, and promotion of the individual and business action towards energy sustainability. Micro energy sustainability can be influenced by;

- the government raising awareness and changing attitudes

- promotion of the individual and business action

- local governments

- CHP - combined heat and power

|

Combined heat and power (Microgeneration Technologies)

|

Energy security

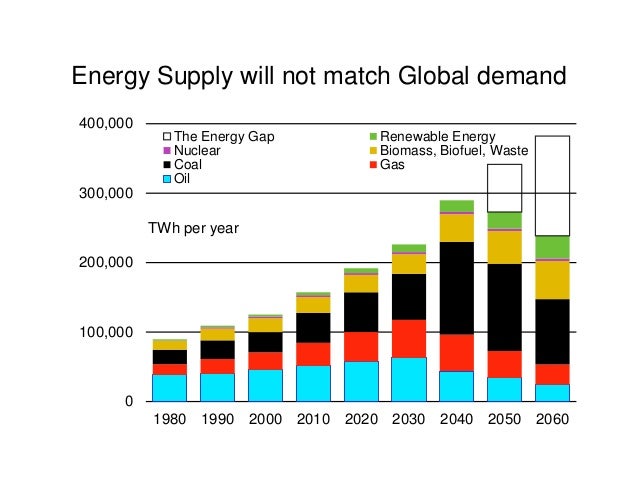

Energy security can be influenced by energy demand/supply trends and forecasting, demand response versus energy efficiency, and smart grids.

Energy security is the association between national security and the availability of natural resources for energy consumption. Access to cheap energy has become essential to the functioning of modern economies. However, the uneven distribution of energy supplies among countries has lead to significant vulnerabilities.

|

EU energy security

|

- Interdependence on countries for energy

- Some countries have more natural resources than others.

- Energy demand:

- The flow of energy over the course of a certain period of time is rarely constant

- there are particular periods during the night where energy use is at a minimum.

- It is important to target and predict energy patterns because overconsumption of natural resources lead to a deficit of sources for energy.

- Energy cannot easily be stored = energy wastage

- Demand and supply trends need to be predicted carefully.

Smart grid

A smart grid is a modernized electrical grid that uses analogue or digital information and communications technology to gather and act on information, such as information about the behaviors of suppliers and consumers, in an automated fashion to improve the efficiency, reliability, economics, and sustainability of the production and distribution of electricity.