The development of increasingly sophisticated production systems is transforming the way products are made.

Craft production

Craft-production is a small-scale production process centered on manual skills. This type of production makes a single, unique, product form start to finish. The product is mostly based on the requirements of the customer.

|

| A Craftsman at work |

- Craft production tends to be labor intensive and often highly skilled labor is required.

- Is a small scale production process

Mechanized production

Mechanized production is a volume production process involving machines controlled by humans. In other words, machinery is used to carry out some or all of the repetitive tasks in a production process.

- May involve using jigs and templates to ensure quality control,

- Using conveyor belts to control the rate of production and to keep components flowing from one process to the next.

Automated production

The term automation refers to a wide variety of systems and processes that operate with little or no human intervention. In most automation systems, control is exercised by the system itself, through control devices that sense changes in conditions.

|

| Automated Assembly |

- A volume production process involving machines controlled by computers.

Assembly line production

Assembly line production is the mass-production of a product via a flow line based on the interchangeability of parts, pre-processing of materials, standardization and work division.

- Each manufacturing task is divided up into basic stages.

- Each stage is carried out using specialist labor and equipment

- A flow line (like a conveyor belt) moves each part from one stage to the next. This controls the rate of production

This makes each individual task repetitive. The benefit to the consumer is cheaper products.

Mass customization

Mass customization is a production process that combines elements of mass production with those of bespoke tailoring. products are adapted to meet a customer's individual needs, so no two items are the same.

For example, Nike ID allows customers to customize their Nike clothing and footwear before buying:

|

| Customizing shoes on NikeiD |

Computer numerical control (CNC)

Refers specifically to the computer control of machines for the purpose of manufacturing complex parts in metal and other materials. Machines are controlled by a program commonly called "G Code". Each code is assigned to a particular operation or process. The code controls X,Y, and Z movements and also sets the speed.

CAD (Computer aided Design) systems are linked to the manufacturing equipment which also controlled by computer, they form an integrated CAD/CAM (Computer-Aided Manufacture) system.

- consistent accuracy

- elimination of error

- lowered labor costs

Design for manufacture (DfM): design for materials, design for process, design for assembly, design for disassembly

Designers design specifically for optimum use of existing manufacturing capability. DFM is the process of designing products to improve the ease of manufacture, i.e. more manufacturability.

Design for materials

Design for materials - designing in relation to materials during processing

For example, a green designer would consider the use of recycled materials in the design of the product; they would consider the availability of materials locally and thus can affect the manufacturing process.

|

| Considering different materials to best design |

Design for process

Designing to enable the product to be manufactured using a specific manufacturing process for example, injection molding.

|

| Examples of processes |

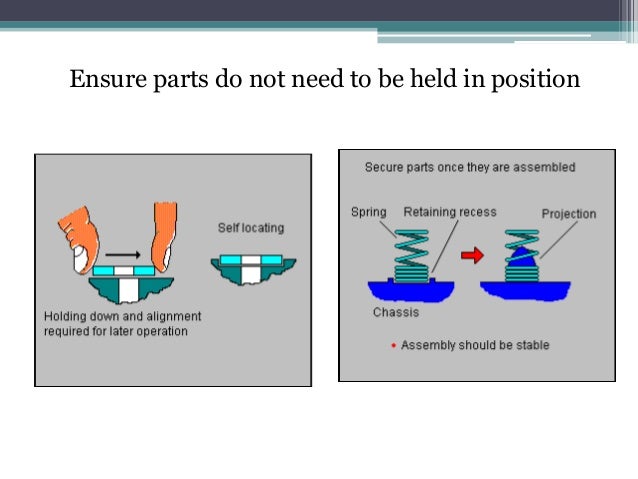

Design for assembly

Design for assembly is designing taking account of assembly at various levels, for example, component to component, components into sub-assemblies and sub-assemblies into complete products.

Design for disassembly

Design for disassembly is designing a product so that when it becomes obsolete it can easily and economically be taken apart, the components reused or repaired, and the materials repurposed or recycled.

No comments:

Post a Comment